Home /

Expert Answers /

Electrical Engineering /

the-cross-section-and-design-rules-of-the-piezo-mump-microfabrication-process-with-aluminum-nitride-pa394

(Solved): The cross section and design rules of the Piezo-MUMP microfabrication process with Aluminum Nitride ...

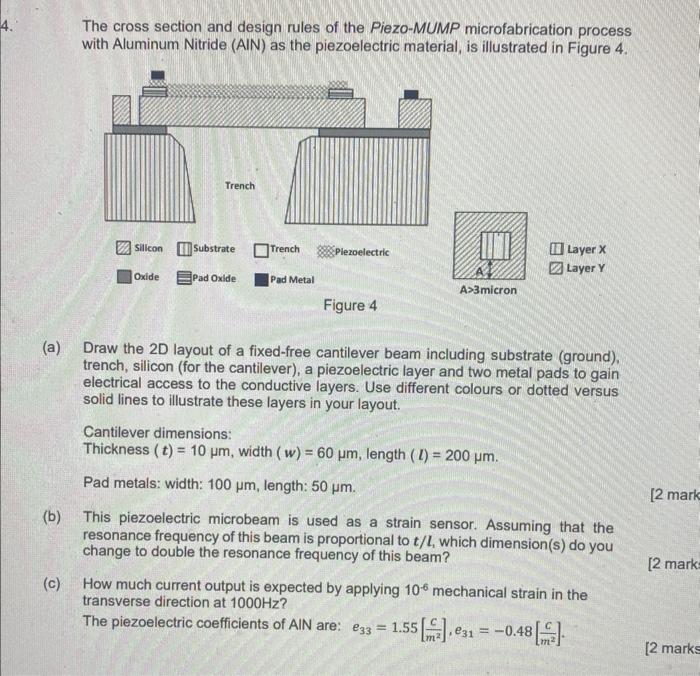

The cross section and design rules of the Piezo-MUMP microfabrication process with Aluminum Nitride (AIN) as the piezoelectric material, is illustrated in Figure 4. (a) Draw the 2D layout of a fixed-free cantilever beam including substrate (ground), trench, silicon (for the cantilever), a piezoelectric layer and two metal pads to gain electrical access to the conductive layers. Use different colours or dotted versus solid lines to illustrate these layers in your layout. Cantilever dimensions: Thickness \( (t)=10 \mu \mathrm{m} \), width \( (w)=60 \mu \mathrm{m} \), length \( (l)=200 \mu \mathrm{m} \). Pad metals: width: \( 100 \mu \mathrm{m} \), length: \( 50 \mu \mathrm{m} \). [2 mark (b) This piezoelectric microbeam is used as a strain sensor. Assuming that the resonance frequency of this beam is proportional to \( t / L \), which dimension(s) do you change to double the resonance frequency of this beam? (c) How much current output is expected by applying \( 10^{-6} \) mechanical strain in the transverse direction at \( 1000 \mathrm{~Hz} \) ? The piezoelectric coefficients of AlN are: \( e_{33}=1.55\left[\frac{c}{\mathrm{~m}^{2}}\right], e_{31}=-0.48\left[\frac{c}{\mathrm{~m}^{2}}\right] \).

Expert Answer

A) To draw the 2D layout of a fixed-free cantilever beam using the Piezo-MUMP microfabrication process with Aluminum Nitride (AIN) as the piezoelectri