(Solved): Shown below is a typical aircraft pressure bulkhead made of Carbon Fibre Reinforced Polymer (CFRP). ...

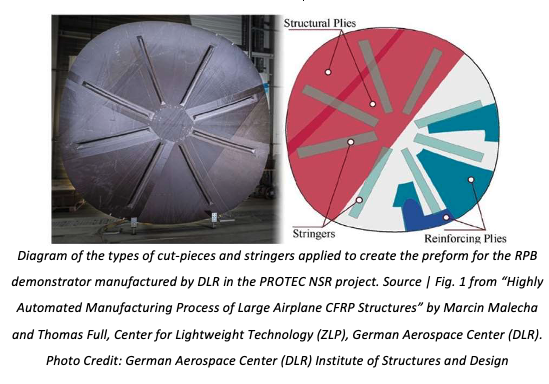

Shown below is a typical aircraft pressure bulkhead made of Carbon Fibre Reinforced Polymer (CFRP). In comparison to the current traditional pressure bulkhead for the A320 product family, made of riveted aluminium components, the thermoplastic CFRP version reportedly offers the same mechanical properties but with a 10-15% weight savings, and a roughly 50% reduction in production time which cuts manufacturing costs. The thermoplastic pressure bulkhead reportedly offers all the characteristics needed for a next-generation aircraft.

You have been tasked by your manager to identify the best manufacturing method to manufacture this CFRP pressure bulkhead. Give reasons for the selection of your method. You may use the tables given below for guidance.

Expert Answer

Carbon fiber-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that