Home /

Expert Answers /

Mechanical Engineering /

nbsp-nbsp-4-1-introduction-gas-tungsten-arc-welding-gtaw-also-known-as-tungsten-inert-ga-pa937

(Solved): 4.1 Introduction Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Ga ...

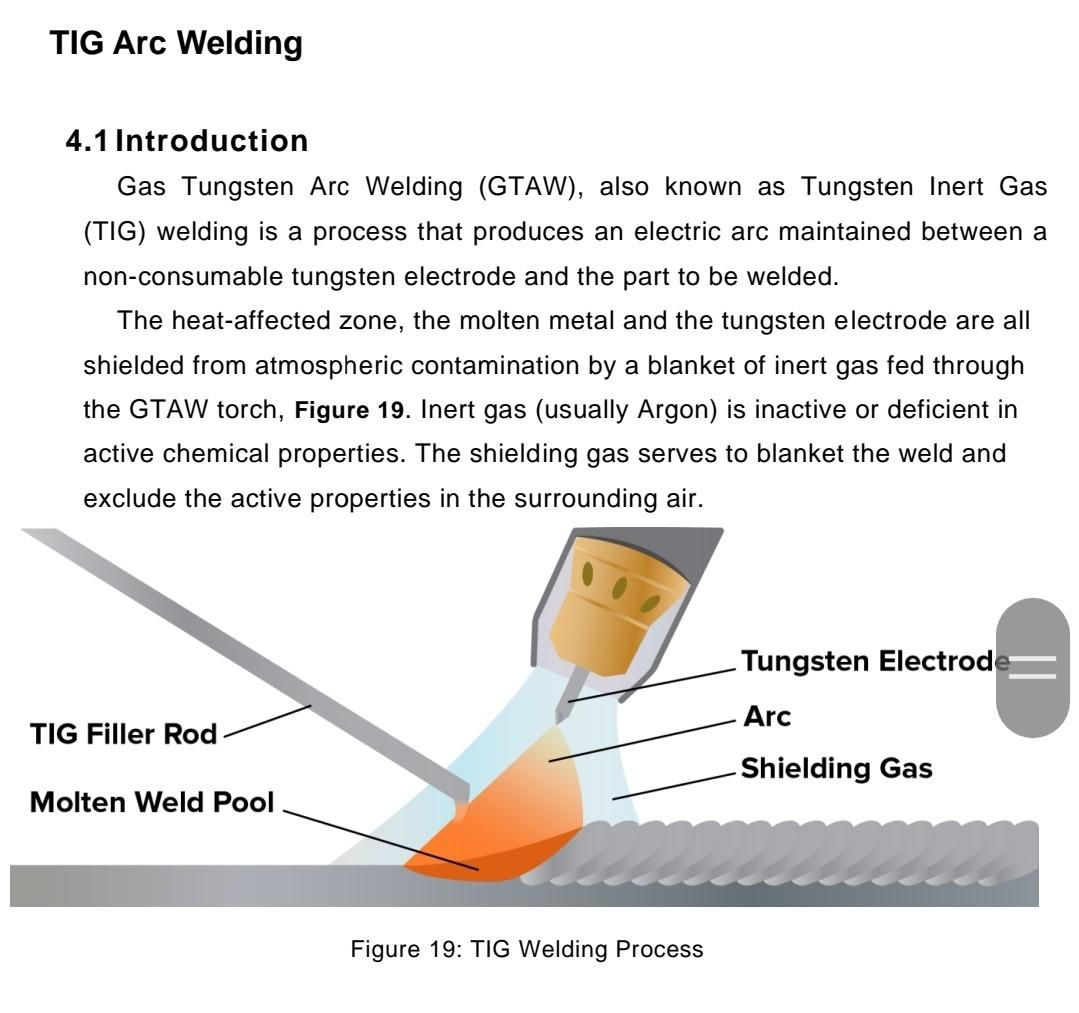

4.1 Introduction Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding is a process that produces an electric arc maintained between a non-consumable tungsten electrode and the part to be welded. The heat-affected zone, the molten metal and the tungsten electrode are all shielded from atmospheric contamination by a blanket of inert gas fed through the GTAW torch, Figure 19. Inert gas (usually Argon) is inactive or deficient in active chemical properties. The shielding gas serves to blanket the weld and exclude the active properties in the surrounding air. Figure 19: TIG Welding Process

4.6 Requirement 1. Describe the TIG welding process illustrating 2. Describe the electrode properties. 3. Describe the gas function. 4. Mention the main advantages and disadvantages of the TIG welding. 5. Mention the differences between arc welding and TIG welding. 6. Describe three TIG welding defects, their reason, symbol and solution.

Expert Answer

TIG: Tungsten Inert Gas TIG welding process the arc is formed between a pointed tungsten electrode and the workpiece in an inert atmosphere of argon o