Home /

Expert Answers /

Electrical Engineering /

draw-the-ladder-diagram-of-the-system-whose-scenario-is-given-below-and-design-the-scada-screens-s-pa784

(Solved): Draw the ladder diagram of the system whose scenario is given below and design the SCADA screens. S ...

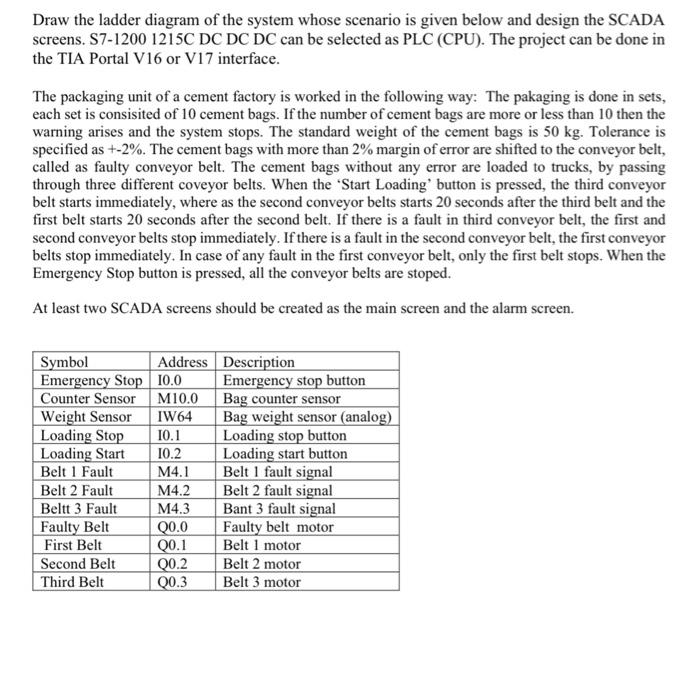

Draw the ladder diagram of the system whose scenario is given below and design the SCADA screens. S7-1200 1215 C DC DC DC can be selected as PLC (CPU). The project can be done in the TIA Portal V16 or V17 interface. The packaging unit of a cement factory is worked in the following way: The pakaging is done in sets, each set is consisited of 10 cement bags. If the number of cement bags are more or less than 10 then the warning arises and the system stops. The standard weight of the cement bags is . Tolerance is specified as . The cement bags with more than margin of error are shifted to the conveyor belt, called as faulty conveyor belt. The cement bags without any error are loaded to trucks, by passing through three different coveyor belts. When the 'Start Loading' button is pressed, the third conveyor belt starts immediately, where as the second conveyor belts starts 20 seconds after the third belt and the first belt starts 20 seconds after the second belt. If there is a fault in third conveyor belt, the first and second conveyor belts stop immediately. If there is a fault in the second conveyor belt, the first conveyor belts stop immediately. In case of any fault in the first conveyor belt, only the first belt stops. When the Emergency Stop button is pressed, all the conveyor belts are stoped. At least two SCADA screens should be created as the main screen and the alarm screen.